Recent Posts

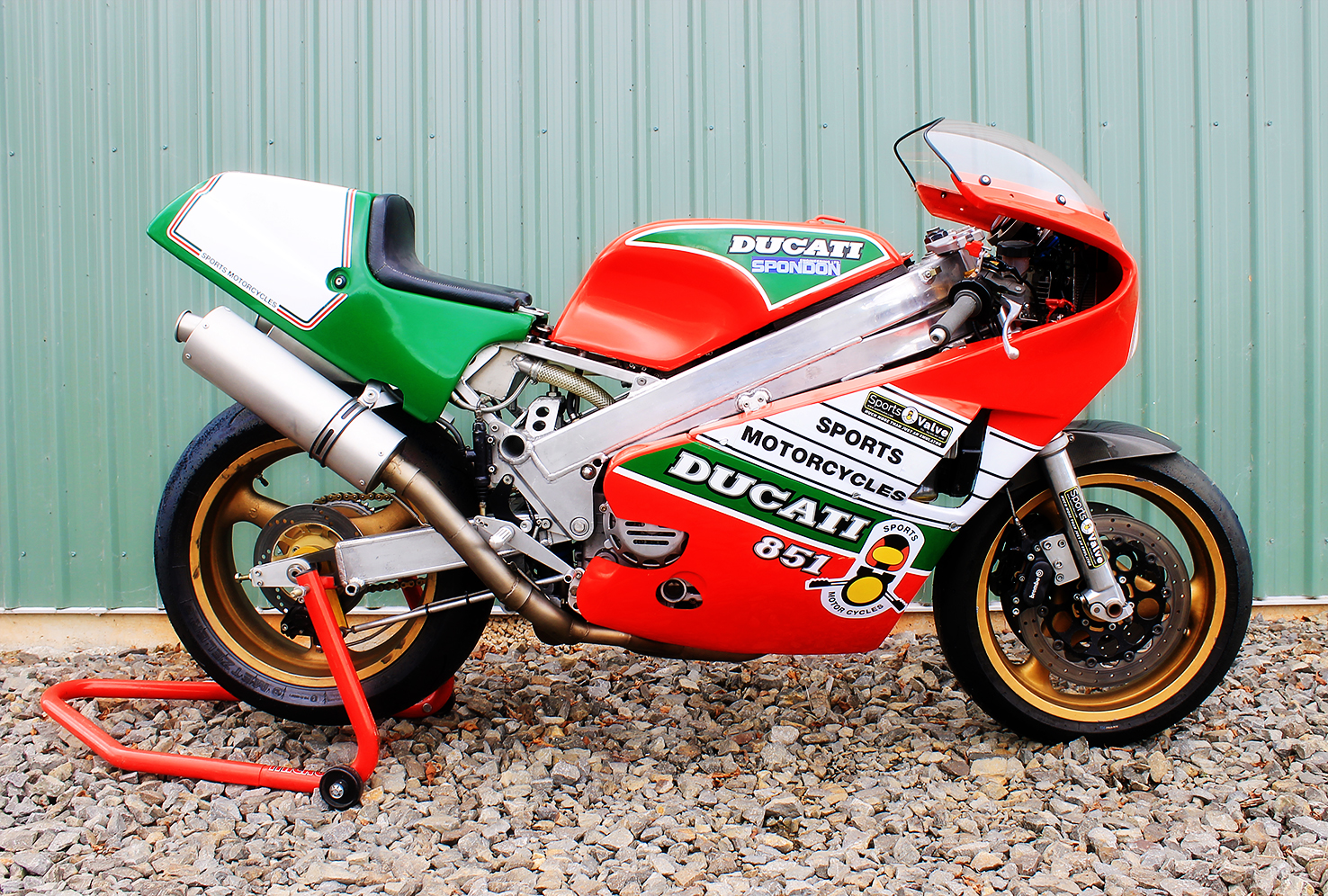

A closer look at the Spondon Ducati

Posted on

I've had a lot of questions recently about our Sports Motorcycles Spondon as it's quite a rare beast, so I thought I'd write up some technical points of interest.

- FRAME

- SPECIFICATIONS

- COOLING SYSTEM MODIFICATIONS

The alloy beam frame was manufactured by Spondon Engineering in Derbyshire - which is no longer in business as such. After the brilliant engineer Bob Stevenson died the remains of the business were bought by Norton a few years ago. Spondon manufactured approximately 30 frames of this particular type, originally for the 2 valve air cooled Ducati engines, and manufactured exclusively for Sports Motorcycles. The further development of this chassis during the early ninties resulted in a new design noteably sporting an alloy fabricated single-sided swing arm.

The chief designer at Ducati (Massimo Bordi) took great interest in this later chassis, having numerous conversations with Steve Wynne primarily regarding the merits of a single sided swing arm. However, Bordi had his own restrictions as the design brief at Ducati was driven to maintain the existing trellis frame concept. As history will record, the ground-breaking 916 became the perfect amalgamation of these two critical features. Trellis frame and single sided swing arm.

This particular chassis is one of two (number two actually) pre-production frames made for Steve Wynne's evaluation (stamped SPE-600DUC-372). The only further modification to be made to the production run was to the machined aluminium billet swing arm pivot block.The internal pocket machining was transferred to the outside rather than being hidden from view. Steve considered the rising rate rear suspension linkage to be one of the best in the business.

At some point during the batch, the subframe became welded, rather than bolted to the main spar.

One inherent niggle has been the short swing arm designed for those 16" wheels considered to be a huge technological leap forward in 1988. As can be seen from the pictures the chain adjustment is resricted to the rear of the available movement as the 17" tyre now runs so close to the forward cross brace tube. The next mod will be to re-manufacture the spindle adjuster blocks on the swing arm to allow full movement.

This particular pre-production chassis was built into a race bike to explore the limits of the new design and used in anger in the 'Battle of the Twins' UK National Championship from 1989 - 1992. Originally fitted with a 750 Pantah engine, and latterly with an 888.

The bike was sold on in the early nineties and fell into obscurity for some years before emerging as a custom special fitted with a 906 paso motor. A very good friend of mine happened to buy it in 2010 but he didn't really know why (Like most of us I guess). I recognised the chassis immediately and it took little persuasion to return the bike back to it's roots and get it back on the track where it truly belongs.

Now rebuilt into it's current guise, it once again forms a key part of the Sports Motorcycles race team, and will be campaigned in the Pre-89 F1 Post Classic Series.

SPECIFICATIONS

Frame:

Spondon prototype aluminium Beam Chassis, manufactured 1988

Bodywork:

Spondon race pattern fairing/seat (fibre glass). Aluminium Fuel Tank

Forks:

Honda RC30, 1987. Fitted with our own Sports valves.

Brakes:

320mm Floating C/I Rotors, Brembo 32/32 Calipers. 230mm rear disc.

Wheels:

Marvic magnesium - 3.50 x 17, 5.50 x 17

Engine:

Ducati water-colled 8 Valve, 1026CC, 98 bore x 68 stroke

Output 142HP @ 9,800 RPM

Weber Marelli fuel injection, 54mm throttle bodies. Two injectors per cylinder. Fuel pressure 5 bar.

6 Speed semi-close ratio 6-speed Gearbox

37mm Inlet Valves

32mm Exhaust Valves

'G' Inlet and Exhaust Valves

52mm Header Pipes, 54mm Muffler entry with 'double-coned' perforated cores

Techtronic's quick shifter.

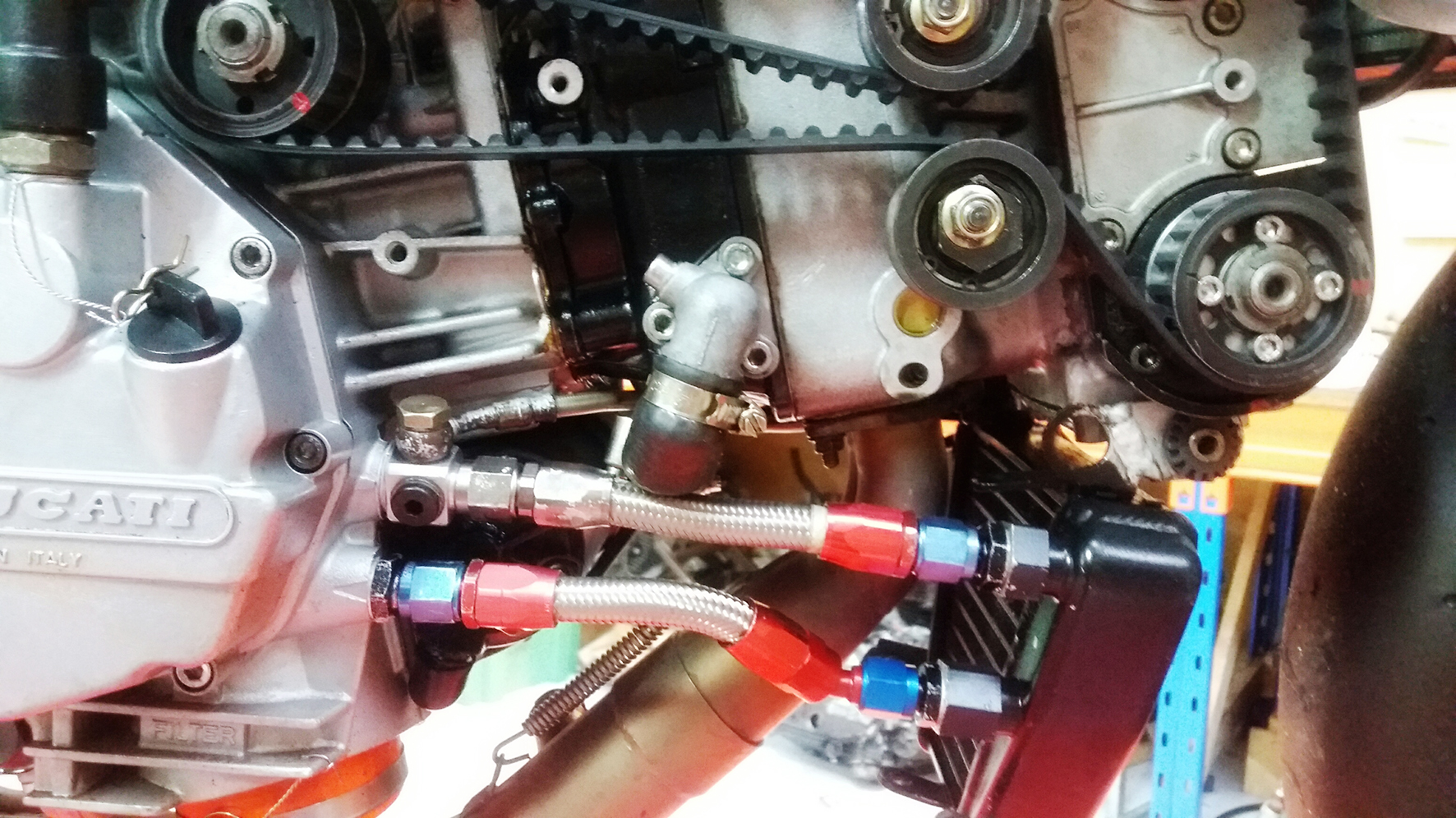

Above. lower front barrel coolant inlet from the pump

THE DEVIL'S IN THE DETAIL. !

COOLING SYSTEM MODIFICATIONS

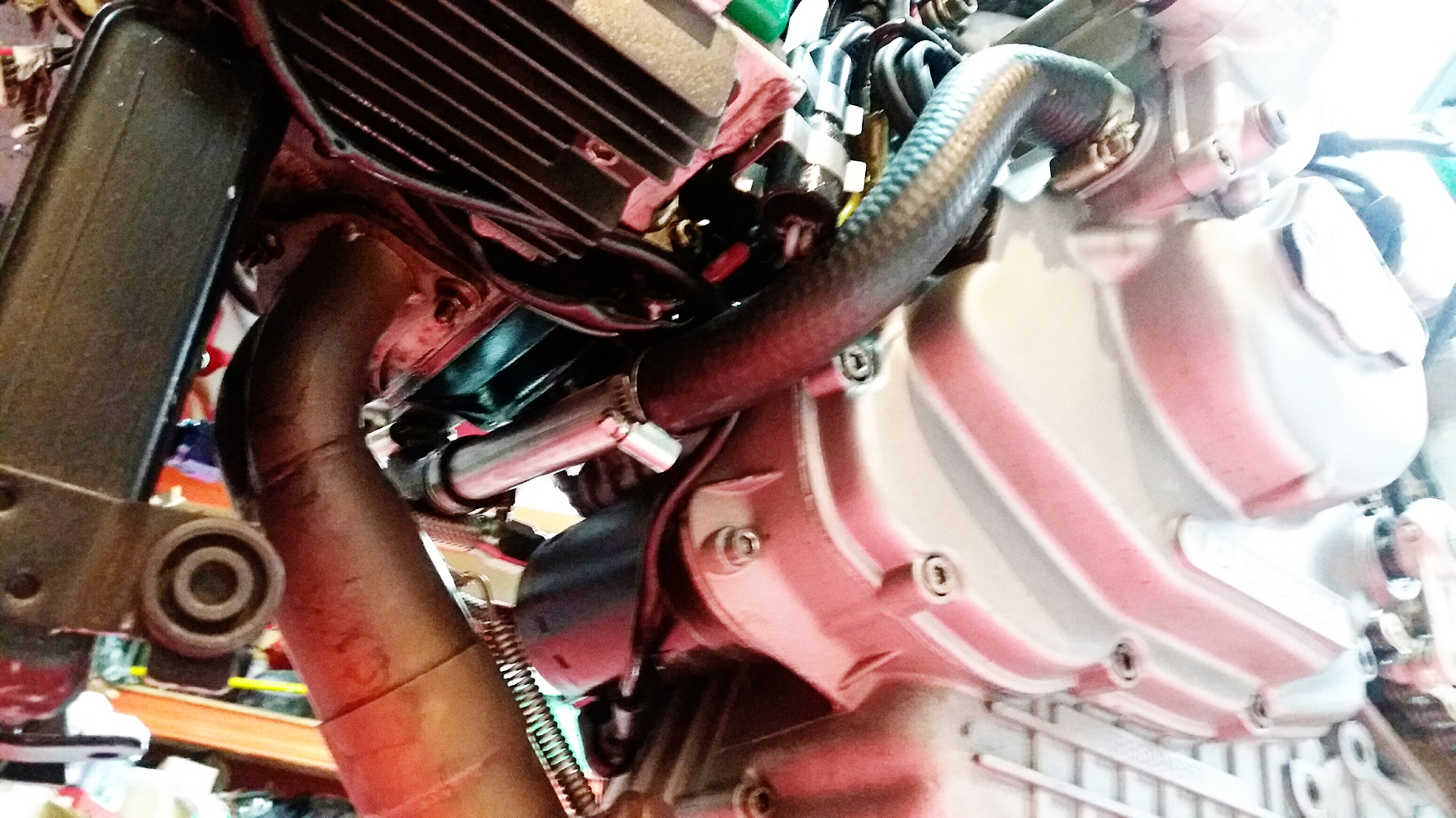

Historically, Ducati always routed the coolant from the pump to each cylinder inlet on the left hand side of the engine. They then fed the coolant back out of each cylinder on the same left hand side. This results in the right hand side of both barrels/heads running extremely hotter than the left side due to the poor coolant flow management.

One major consequence of the unequal barrel temperature is distortion of the cylinder bores. This can only lead to unwanted compression leakage, thus leading to the explanation of utterly cavernous crank case breather boxes found attached to every large capacity Ducati race engine in a desperate effort to cope with the crank case pressure.

Ducati fitted much larger, deeper, heavier (and extremely expensive) radiators to combat higher coolant temperatures as the power output further increased with each subsequent development on their factory race bikes.

Somehow, they seemed to miss the trick.

As you can see from the photos, I route the coolant hoses left to right side across both cylinders from barrel to cyl head and use a standard 749/999 radiator, which is currently half-taped over to achieve a racing temperature of 90 degrees.

Below upper pic. Rear cyl head,front RH view from above. Coolant outlet running downwards then across to the LH side of the engine to join the multiple hose union block (above my battery) on the front cyl head outlet. From there, forwards to join with the radiator top hose.

Below 2nd pic. Pump to lower RH barrel hose.

Below 3rd pic. 142bhp using only 65% of a std road fitment 749 radiator to achieve running temperature of 90deg (and that's on a hot sunny day in NZ).

Loading... Please wait...

Loading... Please wait...